Waste Management Services

Compressed Biogas Solutions

Engineering Services in waste to clean energy

GreenBoxTM

Mini Biogas Plant

Waste Management

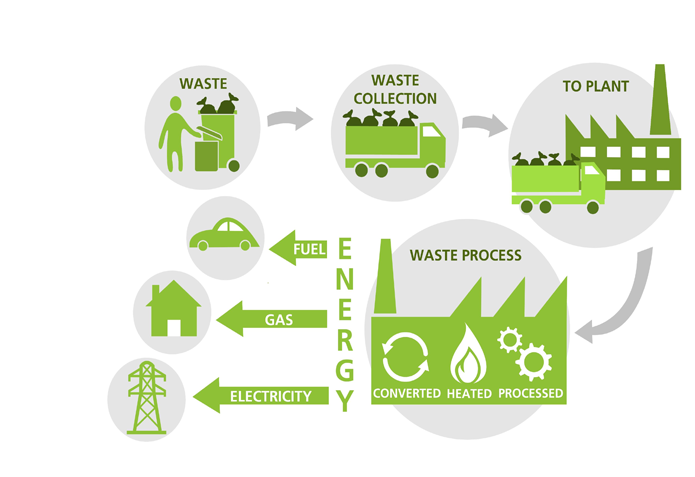

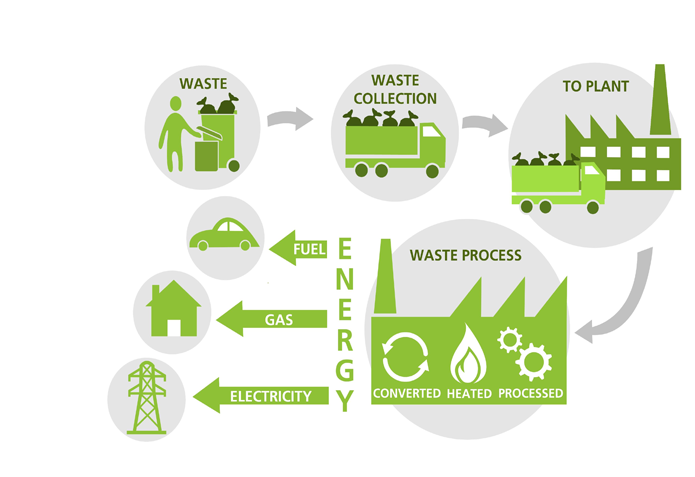

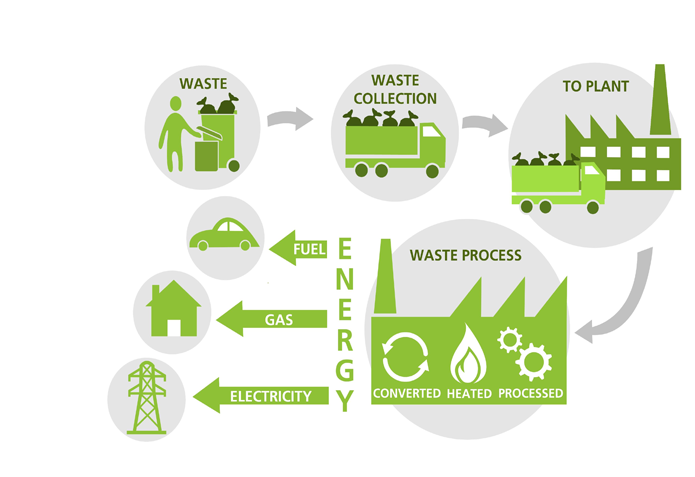

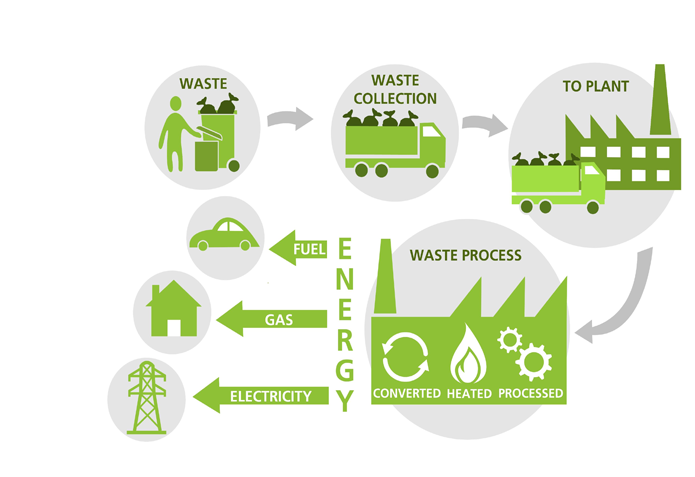

Waste management has become so common a term these days that no one needs to elaborate on it. Yet, if we try to make a deliberate attempt to brief it into a single line, we should say that waste management is the method or activity of complete disposal of society’s waste. But as humanity progressed towards scientific advancement, innovative ideas saturated the human brain. As a result, we not only participate in the disposal of waste anymore but also use it to our advantage.

Green Elephant fabricates biogas from wastes — both organic and inorganic. Our research and development team is in a constant endeavor to discover newer technologies and methods of managing society’s waste streams such as sludge, paper fiber, plastic, and food processing by-products. Moreover, Green Elephant has partnered with MBA Polymers, a global specialist in recycled plastics. MBA Polymers has offices in California, China, and the United Kingdom. Annually, it can process approximately 300 million pounds or 14000 tons of refined plastic garbage. We purvey these refined plastics to a number of the world’s biggest electronics and vehicle manufacturers.

Compressed Biogas Solutions

Green Elephant, the leading CBG (Compressed Biogas) producer in India, offers Compressed Biogas solutions to mostly industrial clients, though others can also facilitate from our services. As one of the market leaders in this industry, we have our own biogas plants — large, medium, and small scale. These plants, where organic waste is converted into biogas, are well equipped with both the latest technologies and the smartest workers. Our largest biogas plant in Satara was built in 2008, followed by the establishment of India’s largest Biogas upgradation plant in 2010 (phase 1) and 2015 (phase 2). Elephant Equity, Madaus Capital, and other European investors are promoting the Satara facility, which is being funded by the Indian Renewable Energy Development Agency (IREDA) with the support of KfW Bank, Germany.

Industrial customers are supplied with Biogas and CBG by Green Elephant under long-term agreements. Every day, the plant uses 600 tons of waste and creates 2800 cubic meters of biogas. Next, the biogas is processed to generate 11,000 normal cubic meters (Nm³) of CBG every day which is afterward given to our client allowing them to go towards green fuel. It’s hour extreme honor to state that this plant of ours is one of the largest technologically enhanced plants of its kind in Asia.

Engineering Services in waste to clean energy

Temperature and weather patterns are fluctuating over time, which is a matter of grave concern for the twenty-first century, necessitating a new flow of cleaner energy derived from renewable sources. That is why we are extending the scope of our services by collaborating with experts in the USA and various other European countries to serve this cause with an application-oriented engineering focus. And thus we’re also enabling ourselves to deliver accurate and efficient consultancy and engineering services to clients in this sector.

Renewable energy engineers employ a mix of study, mathematical calculations, designing, and experimentation to develop green energy options that do not hurt the climate. As of now, our utmost priority in this regard is to expand and extend our engineering services worldwide after its marvelous success. On a consultation and EPC approach, we seek to propound our clients a one-stop escape for all types of technical requirements in this area.

GreenBoxTM

The most in-demand product in any business has always been convenience, and this awareness of ours has led us to not only figure out this pain point of the market but also address it with a solution. It’s a quotidian fact that almost every industrial business generates waste. But not everyone can own, afford or maintain a biogas plant on a regular basis. Well, to comfort them in this regard, after extensive research, we devised the concept of a mini biogas plant — the Green Box. It is a single remedy to the multiple issues of a business including low maintenance, and lesser space requirement.

The capacity of this technology is also worth discussing. It can produce 40 m3 to 160 m3 of biogas daily by processing 10 kg to 2000 kg of organic waste. The Green Box produces profits through the export of biogas or power, as well as advantages to the owner by producing fertilizer and reducing trash, making it cost-viable. The Green Box integrates ecological and economic objectives in an innovative approach.

Waste Management Services

Compressed Biogas Solutions

Engineering Services in waste to clean energy

GreenBoxTM

Mini Biogas Plant

Waste Management

Waste management has become so common a term these days that no one needs to elaborate on it. Yet, if we try to make a deliberate attempt to brief it into a single line, we should say that waste management is the method or activity of complete disposal of society’s waste. But as humanity progressed towards scientific advancement, innovative ideas saturated the human brain. As a result, we not only participate in the disposal of waste anymore but also use it to our advantage.

Green Elephant fabricates biogas from wastes — both organic and inorganic. Our research and development team is in a constant endeavor to discover newer technologies and methods of managing society’s waste streams such as sludge, paper fiber, plastic, and food processing by-products. Moreover, Green Elephant has partnered with MBA Polymers, a global specialist in recycled plastics. MBA Polymers has offices in California, China, and the United Kingdom. Annually, it can process approximately 300 million pounds or 14000 tons of refined plastic garbage. We purvey these refined plastics to a number of the world’s biggest electronics and vehicle manufacturers.

Compressed Biogas Solutions

Green Elephant, the leading CBG (Compressed Biogas) producer in India, offers Compressed Biogas solutions to mostly industrial clients, though others can also facilitate from our services. As one of the market leaders in this industry, we have our own biogas plants — large, medium, and small scale. These plants, where organic waste is converted into biogas, are well equipped with both the latest technologies and the smartest workers. Our largest biogas plant in Satara was built in 2008, followed by the establishment of India’s largest Biogas upgradation plant in 2010 (phase 1) and 2015 (phase 2). Elephant Equity, Madaus Capital, and other European investors are promoting the Satara facility, which is being funded by the Indian Renewable Energy Development Agency (IREDA) with the support of KfW Bank, Germany.

Industrial customers are supplied with Biogas and CBG by Green Elephant under long-term agreements. Every day, the plant uses 600 tons of waste and creates 2800 cubic meters of biogas. Next, the biogas is processed to generate 11,000 normal cubic meters (Nm³) of CBG every day which is afterward given to our client allowing them to go towards green fuel. It’s hour extreme honor to state that this plant of ours is one of the largest technologically enhanced plants of its kind in Asia.

Engineering Services in waste to clean energy

Temperature and weather patterns are fluctuating over time, which is a matter of grave concern for the twenty-first century, necessitating a new flow of cleaner energy derived from renewable sources. That is why we are extending the scope of our services by collaborating with experts in the USA and various other European countries to serve this cause with an application-oriented engineering focus. And thus we’re also enabling ourselves to deliver accurate and efficient consultancy and engineering services to clients in this sector.

Renewable energy engineers employ a mix of study, mathematical calculations, designing, and experimentation to develop green energy options that do not hurt the climate. As of now, our utmost priority in this regard is to expand and extend our engineering services worldwide after its marvelous success. On a consultation and EPC approach, we seek to propound our clients a one-stop escape for all types of technical requirements in this area.

GreenBoxTM

The most in-demand product in any business has always been convenience, and this awareness of ours has led us to not only figure out this pain point of the market but also address it with a solution. It’s a quotidian fact that almost every industrial business generates waste. But not everyone can own, afford or maintain a biogas plant on a regular basis. Well, to comfort them in this regard, after extensive research, we devised the concept of a mini biogas plant — the Green Box. It is a single remedy to the multiple issues of a business including low maintenance, and lesser space requirement.

The capacity of this technology is also worth discussing. It can produce 40 m3 to 160 m3 of biogas daily by processing 10 kg to 2000 kg of organic waste. The Green Box produces profits through the export of biogas or power, as well as advantages to the owner by producing fertilizer and reducing trash, making it cost-viable. The Green Box integrates ecological and economic objectives in an innovative approach.

Waste Management Services

Waste Management

Waste management has become so common a term these days that no one needs to elaborate on it. Yet, if we try to make a deliberate attempt to brief it into a single line, we should say that waste management is the method or activity of complete disposal of society’s waste. But as humanity progressed towards scientific advancement, innovative ideas saturated the human brain. As a result, we not only participate in the disposal of waste anymore but also use it to our advantage.

Green Elephant fabricates biogas from wastes — both organic and inorganic. Our research and development team is in a constant endeavor to discover newer technologies and methods of managing society’s waste streams such as sludge, paper fiber, plastic, and food processing by-products. Moreover, Green Elephant has partnered with MBA Polymers, a global specialist in recycled plastics. MBA Polymers has offices in California, China, and the United Kingdom. Annually, it can process approximately 300 million pounds or 14000 tons of refined plastic garbage. We purvey these refined plastics to a number of the world’s biggest electronics and vehicle manufacturers.

Waste Management Services

Waste Management

Waste management has become so common a term these days that no one needs to elaborate on it. Yet, if we try to make a deliberate attempt to brief it into a single line, we should say that waste management is the method or activity of complete disposal of society’s waste. But as humanity progressed towards scientific advancement, innovative ideas saturated the human brain. As a result, we not only participate in the disposal of waste anymore but also use it to our advantage.

Green Elephant fabricates biogas from wastes — both organic and inorganic. Our research and development team is in a constant endeavor to discover newer technologies and methods of managing society’s waste streams such as sludge, paper fiber, plastic, and food processing by-products. Moreover, Green Elephant has partnered with MBA Polymers, a global specialist in recycled plastics. MBA Polymers has offices in California, China, and the United Kingdom. Annually, it can process approximately 300 million pounds or 14000 tons of refined plastic garbage. We purvey these refined plastics to a number of the world’s biggest electronics and vehicle manufacturers.

Compressed Biogas Solutions

Compressed Biogas Solutions

Green Elephant, the leading CBG (Compressed Biogas) producer in India, offers Compressed Biogas solutions to mostly industrial clients, though others can also facilitate from our services. As one of the market leaders in this industry, we have our own biogas plants — large, medium, and small scale. These plants, where organic waste is converted into biogas, are well equipped with both the latest technologies and the smartest workers. Our largest biogas plant in Satara was built in 2008, followed by the establishment of India’s largest Biogas upgradation plant in 2010 (phase 1) and 2015 (phase 2). Elephant Equity, Madaus Capital, and other European investors are promoting the Satara facility, which is being funded by the Indian Renewable Energy Development Agency (IREDA) with the support of KfW Bank, Germany.

Industrial customers are supplied with Biogas and CBG by Green Elephant under long-term agreements. Every day, the plant uses 600 tons of waste and creates 2800 cubic meters of biogas. Next, the biogas is processed to generate 11,000 normal cubic meters (Nm³) of CBG every day which is afterward given to our client allowing them to go towards green fuel. It’s hour extreme honor to state that this plant of ours is one of the largest technologically enhanced plants of its kind in Asia.

Compressed Biogas Solutions

Compressed Biogas Solutions

Green Elephant, the leading CBG (Compressed Biogas) producer in India, offers Compressed Biogas solutions to mostly industrial clients, though others can also facilitate from our services. As one of the market leaders in this industry, we have our own biogas plants — large, medium, and small scale. These plants, where organic waste is converted into biogas, are well equipped with both the latest technologies and the smartest workers. Our largest biogas plant in Satara was built in 2008, followed by the establishment of India’s largest Biogas upgradation plant in 2010 (phase 1) and 2015 (phase 2). Elephant Equity, Madaus Capital, and other European investors are promoting the Satara facility, which is being funded by the Indian Renewable Energy Development Agency (IREDA) with the support of KfW Bank, Germany.

Industrial customers are supplied with Biogas and CBG by Green Elephant under long-term agreements. Every day, the plant uses 600 tons of waste and creates 2800 cubic meters of biogas. Next, the biogas is processed to generate 11,000 normal cubic meters (Nm³) of CBG every day which is afterward given to our client allowing them to go towards green fuel. It’s hour extreme honor to state that this plant of ours is one of the largest technologically enhanced plants of its kind in Asia.

GreenBoxTM

Mini Biogas Plant

GreenBoxTM

The most in-demand product in any business has always been convenience, and this awareness of ours has led us to not only figure out this pain point of the market but also address it with a solution. It’s a quotidian fact that almost every industrial business generates waste. But not everyone can own, afford or maintain a biogas plant on a regular basis. Well, to comfort them in this regard, after extensive research, we devised the concept of a mini biogas plant — the Green Box. It is a single remedy to the multiple issues of a business including low maintenance, and lesser space requirement.

The capacity of this technology is also worth discussing. It can produce 40 m3 to 160 m3 of biogas daily by processing 10 kg to 2000 kg of organic waste. The Green Box produces profits through the export of biogas or power, as well as advantages to the owner by producing fertilizer and reducing trash, making it cost-viable. The Green Box integrates ecological and economic objectives in an innovative approach.

GreenBoxTM

Mini Biogas Plant

GreenBoxTM

The most in-demand product in any business has always been convenience, and this awareness of ours has led us to not only figure out this pain point of the market but also address it with a solution. It’s a quotidian fact that almost every industrial business generates waste. But not everyone can own, afford or maintain a biogas plant on a regular basis. Well, to comfort them in this regard, after extensive research, we devised the concept of a mini biogas plant — the Green Box. It is a single remedy to the multiple issues of a business including low maintenance, and lesser space requirement.

The capacity of this technology is also worth discussing. It can produce 40 m3 to 160 m3 of biogas daily by processing 10 kg to 2000 kg of organic waste. The Green Box produces profits through the export of biogas or power, as well as advantages to the owner by producing fertilizer and reducing trash, making it cost-viable. The Green Box integrates ecological and economic objectives in an innovative approach.

Engineering Services in waste to clean energy

Engineering Services in waste to clean energy

Temperature and weather patterns are fluctuating over time, which is a matter of grave concern for the twenty-first century, necessitating a new flow of cleaner energy derived from renewable sources. That is why we are extending the scope of our services by collaborating with experts in the USA and various other European countries to serve this cause with an application-oriented engineering focus. And thus we’re also enabling ourselves to deliver accurate and efficient consultancy and engineering services to clients in this sector.

Renewable energy engineers employ a mix of study, mathematical calculations, designing, and experimentation to develop green energy options that do not hurt the climate. As of now, our utmost priority in this regard is to expand and extend our engineering services worldwide after its marvelous success. On a consultation and EPC approach, we seek to propound our clients a one-stop escape for all types of technical requirements in this area.